sales@sapthagroup.com

About Us

Saptha Innovations – Authorized Channel Partner for AO Smith Heat Pumps & Grundfos Pumps. Your Trusted Partner for Energy-Efficient Pumping Solutions serving Bangalore and surrounding areas.

SIMPLE YET MOST EFFICIENT BOOSTER SYSTEM

SIMPLE - FUNCTIONAL - COST EFFECTIVE

With a goal to improvise energy efficiency and to reduce water consumption by optimized pressure management, Grundfos has improved several hydro MPC's functionalities making it a first choice amongst the plumbing Industry.

Hydro MPC is Grundfos premium product in the Hydro Booster portfolio. Its long list of unique features makes it able to handle the operational challenges of any water boosting application with ease.

With HYDRO MPC's PILOT PUMP functionality, you have the opportunity to maintain the booster system efficiency close to its overall design, at all loads. This gives an additional energy savings upto 9% depending upon the consumption profile.

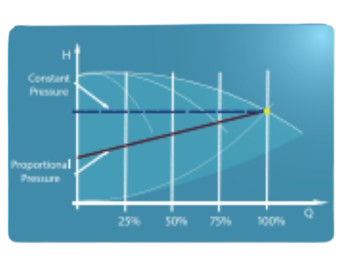

Proportional pressure control compensates for excessive system pressure at tap point by automatically adapting the set point to the actual flow which is unique to ‘GRUNDFOS CU352’ multi pump controller. This functionality further reduces the energy consumption upto 11% over the conventional start/stop booster systems.

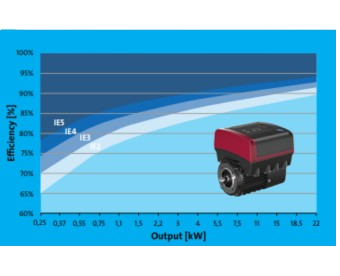

Grundfos permanent magnet motors (PMSM) are designed especially for pump applications, delivering high part-load efficiency. This results in a lower specific energy consumption These motors offer upto 10% energy savings and 25% reduction in payback compared to IE3 motors.

WE AT GRUNDFOS, CONSIDER YOUR WATER DISTRIBUTION SYSTEM AS A WHOLE & OFFER SYSTEM SOLUTIONS WITH BEST POSSIBLE RECOMMENDATIONS ON THE SYSTEM DESIGN & CONTROLS

Grundfos CR/CRI/CRN range of pumps offer remarkable levels of hydraulic efficiency, with laser welded impellers and tight clearances between pressure stages - pumps efficiency assured for years together.

Grundfos's Hydro MPC CU 352 controller a 4th generation controller improvised with decades of field experience and customer feedback offers a host of unmatched unique features to optimize both energy & water consumption.

Due to varying consumption profile, it becomes inevitable to have variable speed drives in the booster system to control the hydraulic capacities in-line with load changes.

With ultra modern sanitary fittings, hydraulic parameters becomes so critical that dedicated variable speed drives for each pumps becomes absolutely a necessity.

.png)

To transfer domestic sewage in:

.png)

To transfer grey & black water in:

.png)

For dewatering of:

GETTING RID OF WASTE WATER IN A SAFE, EFFICIENT AND HYGENIC WAY IS JUST AS IMPORTANT AS ACCESS TO CLEAN DRINKING WATER

Grundfos offers a complete range of wastewater pumps for collecting and transporting wastewater, offering reliabiity and energy efficiency. These pumps are enclosed units with a pump and motor making them suitable for submersible operation; however their construction means that service can be carried out without entering the pit by using auto coupling arrangement wherever feasible

Highly dependable, powerful sewage pumps, designed for handling unscreened raw sewage, acknowledged for their strength, their durability and for innovative features such as SmartTrim impeller clearance adjustment system and SmartSeal for leakage prevention.

Designed for the handling of wastewater, process water and unscreened raw sewage. The pumps can be installed submerged and/or dry.

Submersible sewage grinder pumps for pressurised wastewater pumping designed to optimise performance in your system. The adaptive intelligence built into the AUTOADAPT versions minimises risk factors and reduces costs for installation, commissioning and maintenance.

The DPK.V range of submersible sewage pumps from Grundfos combines durable performance with ease of installation, providing an immediate return on your building service investment. The DPK.V is intended for submersible use in underground sewage collection tanks in or around buildings when cost-effective and reliable sewage transport is required. The compact & service-friendly design and the flexible installation options combine to make the DPK.V the perfect choice.

.png)

The AP/KP pump is designed for liquid transfer and drainage of clean or slightly dirty wastewater with the pump completely or partly submerged in the liquid. The pump can be used for automatic as well as manual operation and can be installed permanently or used as a portable pump.

Drainage pumps designed with semi-open or enclosed impeller for pumping water in a wide range of applications. The pumps are made of robust cast iron, ensuring durable operation.

Contractor pumps for construction dewatering in building and infrastructure sites, designed with semi-open or enclosed impeller. Made of corrosion-resistant materials such as cast iron and high chrome stainless steel for harsh environments

Highest hydraulic efficiency and best non-clogging capabilities

The S-tube offers greater hydraulic efficiency than any other type of wastewater impeller, without compromising free passage. This results in the lowest life cycle cost, trouble free operation and best-in-class non-clogging capabilities.

When you package this innovative, elegant and simple impeller design in the outstanding SE and SL ranges of submersible wastewater pumps and add IE3 motor components and super intelligent controls, we truly believe we are looking at the ultimate in wastewater pumping technology.

With the S- tube, Grundfos sets new standards for wastewater hydraulic design . The S-tube resolves the challenges with sealing, vibration abrasive wear and clogging that owners of wastewater pumping stations have lived with for way too long.

WHY FOCUS ON FREE PASSAGE?

Greater free passage means better solids handling and greater non-clogging capabilities.

Better efficiency combined with better free passage with lower vibrations and the same great features and benefits that the S-tube provides.

.png)

Dedicated controls is a pump control system that combines a large number of advanced function with a large, intuitive and easy-to-use graphic display.

.png)

Reliable, easy to set up and easy to use motor protection for all Grundfos pumps and applications for motors ranging from 3 to 999 Amps and voltages from 100 to 480 VAC that protects the pump motors against under voltage, over voltage and other variations in power supply and overheating.

.png)

Digital controller for water and wastewater application in residential or commercial buildings. GI DPC can also be used for tank filling or water transfer.

.png)

When you team up with Grundfos you benefit from an experienced system supplier who is dedicated to providing you with the best possible solution - underground as well as above ground. In addition to the pump itself, a complete system consists of a specially designed submersible motor, a dedicated electronic motor cycle protection unit and a remote monitoring system. Combining these products you are guaranteed a fully optimised water supply system that will save you energy as well as money.

With the high cost of real estate in densely populated cities, providing space for utilities is often an issue. A 6 sqm of space which would be otherwise occupied by a surface mounted hydro booster system can be saved by opting for a submersible hydro-booster system.

Grundfos offers submersible hydro booster system in two variants Hydro MPC system with

1.Grundfos CUE variable frequency drives as premium

2.Danfoss FC 51/101 variable frequency drives as standard

.png)

Grundfos Solar surface pumps provided the perfect sustainable and cost efficient alternative to irregular water supply solutions in remote locations or for highly specific applications anywhere. These pumps provide individual solutions to water problems where conventional water supply systems fail or simply cannot reach.

Modern buildings are living, breathing organisms powered by interconnected systems. Most of these are directly dependent on pumps to transport water efficiently and Precisely. At Grundfos, we have a holistic approach to commercial buildings. Through intelligent technologies, we create systems that effectively boost performance and reduce energy consumption.

We at Grundfos understand all application areas in the building from water supply to wastewater discharge. With your exact demand as our starting point, we can tailor make Solution that will raise the overall energy performance of your building significantly.

Whether you need a complete pumping system for a new build project or you are looking to replace existing pumps, we have a solution that will boost comfort and energy efficiency of your building. How may we help you?

.png)

Optimized for efficiency & reliability

These pumps are non-self-priming, single-stage, centrifugal volute pumps with axial suction port, radial discharge port and horizontal shaft.

Back pull-out design enables removal of the motor, coupling, bearing bracket and impeller without disturbing the pump housing or pipework

Dynamically balanced rotary assembly as per ISO 1940 - Gr 6.3, minimises vibration levels and improves seal and bearing life.

These are single-stage, non-self-priming, between bearing and centrifugal volute pumps. The axially split design allows easy removal of the top casing and access to the pump components without disturbing the motor or pipework. The compensated double-volute design virtually eliminates radial forces on the shaft and ensures smooth performance throughout the entire operating range.

.png)

These pumps are single-stage, close-coupled pumps with in-line inlet and outlet ports of identical diameter. Is of top pull-out design, motor, pump head and/or motor stool and impeller can be accessed for service without disturbing pipework.

Optimised hydraulics for high efficiency

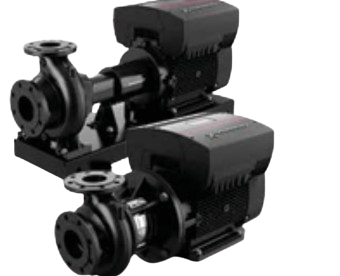

"Close-coupled (NBE, NBGE) and long-coupled (NKE, NKGE) pumps are the perfect choices when you need an end-suction pump with integrated frequency converter for your application. The pumps are all non-self-priming, single-stage, centrif centrifugal volute pumps with axial suction port, radial discharge port and horizontal shaft."

NBE, NBGE, NKE, NKGE in the above mentioned power sizes are all fitted with IE5* permanent-magnet motors.

NBE, NBGE, NKE, NKGE in the above mentioned power sizes are all fitted with IE5* Permanent with integrated frequency converters. Only exemption is the 18.5 kW 4 pole, which exceeds the IE2 demands.

To truly optimise system performance in buildings applications, it’s time to look beyond individual components to intelligent solutions that take care of the entire system. With Grundfos iSOLUTIONS, you get intelligent pumps and components working seamlessly together to enable full system integration and reach a new level of performance with high energy efficiency, reduced complexity, low life-cycle costs and more.

By thinking beyond the pump, and taking the entire pumping system into account, it is possible to optimise the way pumps, drives, controls, protection, measurement and communication units work together as part of one system.

2.25 - 2.2 kW

Motor Details: TPE2 and TPE3 are fitted with IE5* permanent-magnet motors.

Motor Details: TPE Series 1000 and 2000 are fitted with IE5* permanent-magnet motors. TPE SERIES 1000, TPE SERIES 2000

Motor Details: TPE Series 1000 and 2000 are tted with IE3 motors with integrate frequenc converter. The only exemption is the 18.5 kW, low speed motor, which exceeds the IE2demands

are fitted with IE3 motors with integrated frequency converter. The only exemption is the 18.5 kW low-speed motor, which exceeds the IE2 demands

Motor Details: TPE Series 1000 and 2000 are fitted with IE3 or IE4 motors with integrated CUE Frequency converter

A TPE is the perfect choice when you need a single-stage, in-line solution with a state of-the-art motor with frequency drive and mechanical shaft seal. TPEs are close-coupled and thus less sensitive to impurities in the pumped liquid com pared to wet runner circulators. That makes the solution they are part of extra robust and reliable.

.png)

Air conditioning which is termed as Heating Ventilation and Air Conditioning (HVAC), accounts for around 40% of energy consumption in commercial buildings. This value varies regionally based on climatic conditions and other factors.

"Since HVAC is the key contributor to energy consumption, many govern have stepped in to implement efficiency regulations specific to commercial buildings. To name a few, voluntary efficiency standards such as U.S. Green building council (LEED cetification), Energy Star ratings, BREEAM, DGNB and GRIHA standards of TERI in India are gaining significance implementation cance implementation of efficient HVAC systems globally"

Pumps are the heart of any HVAC system. They influence how efficiently other individual components in the HVAC plant work, as well as has a major influence on overall system performance. This calls for a holistic approach in HVAC plant room controls wherein the effect of pump performance over the other major energy consuming components in HVAC plant room such as chillers, cooling towers are weighed and varied, not to save energy on the pump in isolation, but on the improvement of overall plant energy as a whole.

To deliver a system performance as intended by the designer, it is just not the mere supply of pumps that would bring in the plant efficiency, but it is about integrating with the right controls and instrumentation, which would bring in the desired results. Grundfos has decades of expertise in integrating pumps and controls together with its in-house expertise both at pre and post sales, delivering value to HVAC projects through its holistic approach.

Apart from its wide range of pumps for HVAC industry, Grundfos offers controls and automation solutions in Retrieving data. Wait a few seconds and try to cut or copy again. meeting both the current and upcoming trends in the Industry keeping energy performance as the key driver.

.png)

Workhorse of the chilled water pump control which is in use for more than 4 decades from its introduction is still the simplest of choice when it comes to pump control in HVAC plant room. Grundfos Control MPC with CU 352 controller offers unique solution to HVAC industry by having the fexibility to use the pumps hydraulic data internally to optimise the pump performance at all loads precisely. Further all the system components required for the application are from Grundfos - right from controller, variable frequency drive and the differential pressure sensor.

Pumps offered by Grundfos in HVAC application has CED (Cathodic Electrolytic Deposition) coating on all its cast iron parts. Unlike others who use traditional surface coating, this CED coating ensures pump performance for long periods of operation in harsh environments.

.png)

Cathodic Electro Deposit coating (CED coating) is a high-quality dip-painting process where an electrical weld around the products ensures deposition of paint particles as a thin well-controlled layer on the surfaces. The components are immersed in a bath of paint solution. Due to the attraction, paint starts depositing on the component. In spray painting or powder coating, the thickness of paint will not be uniform and it will not be possible to paint in the intricate profiles whereas CED coating will be uniform.

.png)

MAGNA3 pumps cover a broad range of small, medium and large circulator pumps – all fitted with communication equipment and state-of-the-art permanent magnet motors. These smart pumps are perfect for high performance building systems, and fit both heating and cooling applications.

Magna3 features a built-in heat energy meter to monitor system heat energy distribution and consumption in order to avoid system imbalances The heat energy meter has an accuracy of upto +/-10%, depending on the duty point, and will save you the cost of installing a separate energy metering device within your system.

Magna3- FLOW LIMIT function and FLOW ADAPT control mode allows you to set a maximum ow limit allowed. This eliminates the need for pump throttling valves, improving hereby system’s overall energy efficiency.

it is a wet-runner pump with no shaft seals known to operate for more than 30 years in their applications. This non-leakage design make Magna3 maintenance-free resulting reliable operation through out its life.

RELIABILITY THROUGH GENERATIONS The MAGNA3 electronic hardware is a third generation platform built on Grundfos’ 65 years of pump experience, while the pump’s new self-protecting electronics prove that we are still the industry’s electronic pump pioneers 1 MILLION TEST HOURS At Grundfos, we believe in the value of thorough testing. The MAGN A3 has been submitted to more than 1 million test hours in extreme conditions, including alternating pressure tests, high humidity tests as well as high and low-temperature tests.

.png)

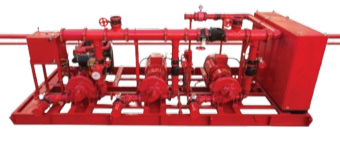

Grundfos skid mounted Fire systems are pre-engineered, design-to-built systems meeting the customer requirements as per local codes and regulations.

.png)

Diaphragm dosing pump with powerful variable speed stepper motor offers high dosing accuracy. Longer maintenance interval due to the universal (chemical resistance of the full-PTFE diaphragm, and reduced energy consumption from the state-of-the-art drive technology).

.png)

Monitoring of typical water quality parameters as well as precise control of disinfection addition or pH adjustment is essential for many water treatment processes. The new Grundfos by s::can DID systems are the perfect combination of s::can’s state-of-the-art digital sensor technology and Grundfos’ experience in PID controlling of dosing and disinfection processes. DID systems are designed to match perfectly with Grundfos dosing pumps, gas dosing systems as well as systems for generation and dosing of chlorine dioxide and hypochlorite.

.png)

DTS dosing tank stations are intended for storing and dosing liquids. Many different configurations can be selected flexibly to fulfil various dosing tasks. Due to the use of high-quality materials, DTS dosing tank stations can be employed for diverse dosing liquids. The selection of materials can be adapted via the configuration to match application and the selected dosing pump.

As they are easy to install, DTS dosing tank stations in combination with the digital dosing pumps DDA, DDC, DDE and DDI are the first choice in the matter of economic efficiency when adding liquids such as coagulants, disinfectants or neutralizing agents to a process in a precise and controlled way

Grundfos offers one of the most extensive product ranges in the market for dosing and disinfection, covering everything from water treatment to disinfection of drinking water in highly sensitive processes.

Grundfos can supply complete dosing pump system for large or small volumes and based on different technologies for cooling water treatment, disinfection, pH adjustment, moreover, the Grundfos range of electronic and electrochemical accessories offers complete control of your dosing and disinfection processes and can be seamlessly integrated into your system. We can also advise and supply disinfection solutions using chlorine compounds such as sodium hypochlorite (NaOCl), and chlorine dioxide (ClO2).

.png)

Grundfos can supply dedicated communication modules and controls for every eventuality, ensuring trouble-free and continuous operation of complex pumping solutions, offering open protocols, control and monitoring with data collection options, all fully compatible with your management system.

For many of our monitoring and control solutions, the packaged software Grundfos PC Tool is used for commissioning, monitoring pump status, adjusting the settings, start/stop of the pumps, query data, generating reports on the operation, and establishing service reports. A huge range of main functions and specialised functions, depending on the application, is also easily accessible via the PC tool, or from the user interface.

Grundfos GO gives you intuitive handheld pump control and full access to the Grundfos online tools on the go. So get ready to save valuable time on pump control, reporting and data collection with the most comprehensive mobile platform on the market.

Open and interoperable data bus networks with open protocols are becoming increasingly important for facility managers operating HVAC or plumbing systems. Grundfos iSOLUTIONS ensures a flexible and cost effective integration of pumps drives or controllers into any BMS, enabling data collection monitoring and complete system control.

For complete control of pump systems, the Grundfos fieldbus concept is the right solution. The innovative Communication Interface Module (CIM) and Communication Interface Unit (CIU) enable data communication via open and interoperable networks such as PROFIBUS DP, Modbus RTU, LONWorks, BACnet MS/TP®, PROFINET IO, Modbus TCP, BACnet IP, and the Grundfos RTU, LONWorks, BACnet MS/TP®, PROFINET IO, Modbus TCP, BACnet IP, and the Grundfos

A pump audit is the ideal way to find out whether your company’s pump system is operating efficiently. A pump audit is an optimal way to reduce CO2 emissions and save money by a thorough analysis of your installations.

DID YOU KNOW

That Approximately 85% of a pumps Life Cycle Costs is incurred by power consumption?

HOW IT WORKS:

A pump auditor will visit your site and conduct a survey in order to collect necessary data. After analysing the data a recommendation will be prepared for you. In this the Life Cycle Costs of your company’s current pump system will be compared with the system you could have if the pumps were changed to more efficient models.

Among other investigations, the auditor will check the overall efficiency of your company’s pumps, look at the initial purchase price of a different pump solution and compare costs for both maintenance and power consumption.

CUT ENERGY CONSUMPTION UP TO 60%

Grundfos’ Pump Audit team has helped everyone from water supply companies to industries and public buildings to cut their energy consumption on average by 40% to 60% just by looking at their pumping systems.

The Grundfos Service Contract can be customized to cover your unique service needs and requirements through the life-cycle of your pumps.

In your daily business, there will be plenty of things requiring your time and attention. Keeping your pumps running reliably and efficiently however, does not have to be one of them. Leave your pump service and maintenance to our qualified Grundfos Service Engineers - no one does it better!

The Grundfos Service Contract can be customized across the following elements:

1. Planned Maintenance Checks

2. Service options

3. Add-ons

The customizable service contract gives you direct access to a wealth of expertise from our Grundfos professionals or trusted partner network, providing you with a number of clear benefits:

Enhanced operational reliability and safety

Opportunity to predict and reduce operating costs

Optimized efficiency and energy consumption (in connection with Energy-Check and Pump Audit)

Increased equipment life span

Easy maintenance record keeping with the Grundfos inspection report

Breakdown prevention and reduced down-time (in connection with Guaranteed response time)

Precise and correct alignment of pump and Motor shaft reducing pump wear and optimizing efficiency.

Thorough and professional commissioning Services for optimum system performance.

Overview of the potential energy savings through analysis of the energy consumption of your pump installations.

A comprehensive auditing service giving hard pump performance facts and identifying potential energy savings in your pumping system.

Get a complete overview with an efficient and cost- effective internet-based control, monitoring and alarm solution.

Fully documented spare parts for pump reliability with flexible ordering and delivery options.

Get an extended period of warranty to get Greater peace in mind.

Vibration measurement can detect the vibration levels of the equipment and therefore assess their condition, thus helping in planning preventive Maintenance and reduce downtime.

Infrared thermography allows us to see Invisible thermal signature of impending damage before it is too late.